We produce welded metal products that meet generally accepted norms and standards, which ensures high quality products.

The production process at our company is based on input quality control of manufactured products and preparation of rolled metal for the production of structural elements. The next stage is the preparatory stage, which is based on the preparation of parts for further production. The finished product is considered after welding, Assembly, and processing. The products are then packaged and prepared for delivery to the customer.

The production facilities and equipment used allow us to produce up to 1000 tons of finished products per month. We guarantee the reliability of metal structures, because we use only high-quality rolled metal, the quality of which is confirmed by factory certificates, the production of metal structures is carried out on high-precision equipment, work is carried out by certified welders and locksmiths.

Metal structures are a complex of interconnected elements (profile pipes, corner, channel, brands, I-beams, etc.) that are assembled in different ways, which allows you to create an object of the required configuration and functionality.

Category: Service

Tags: Production of various types of metal structures, Service

Be the first to review “Production of various types of metal structures” Cancel reply

Related products

-

Rated 0 out of 5

One of the directions of our company is mechanized metal processing or mechanical processing. The bulk of machine parts takes the form and dimensions by…

-

Rated 0 out of 5

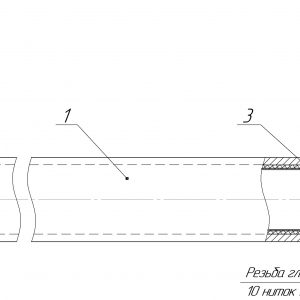

Tubing lining – is a protection on the inner wall of the pipe with a special antifriction and corrosion-resistant lining material EXPE. The surface of…

-

Rated 0 out of 5

Applying paint and protective coatings to metal structures is an important technological process that affects not only the presentable appearance of products, but also provides…

Reviews

There are no reviews yet.